Navigating the Maze: Selecting the Perfect Crystal Resonator for Automotive Applications

The automotive industry is undergoing a seismic shift towards electrification, connectivity, and autonomy. At the heart of this transformation lies a critical, yet often overlooked component: the crystal resonator. Choosing the wrong frequency control device can lead to system failures, communication dropouts, or safety-critical timing errors. This guide cuts through the complexity, helping engineers and procurement specialists make informed decisions when crystal resonator sourcing for their next automotive project.

Figure 1: A high-reliability SMD crystal resonator from Fronter's automotive-grade portfolio. Precision and stability are non-negotiable in vehicle systems.

Step 1: Understand Your Core Requirements

Before diving into datasheets, define your project's non-negotiables:

- Frequency: Is it a 32.768 kHz crystal resonator for real-time clocks (RTC) or an MHz crystal resonator for microcontrollers and CAN bus communication? The quartz crystal model number often indicates its base frequency.

- Form Factor: Surface mount crystal resonator (SMD) types dominate modern designs for their size and suitability for automated assembly. Consider package sizes like SMD3215 or HC49 SMD Crystal.

- Operating Environment: Automotive crystal components must withstand extreme temperatures (-40°C to +125°C+), vibration, and humidity. Not all quartz resonators are created equal for this harsh environment.

- Accuracy & Stability: What is the allowable frequency deviation? Engine control units (ECUs) and radar systems demand high accuracy crystal solutions with tight stability over temperature and time.

Step 2: Match the Resonator Type to the Application

Different frequency control devices serve different purposes. Here’s a quick breakdown for automotive use:

| Application | Recommended Resonator Type | Key Considerations |

|---|---|---|

| Infotainment & Telematics | MHz crystal resonator (e.g., 12-40 MHz), SMD crystal resonator | Stable SMD crystal frequency for processors; may need multiple resonators for different ICs. |

| Body Control Modules (BCM) | 32.768K tuning fork crystal (for RTC), Quartz crystal resonator for main clock | Low-power watch crystal for timekeeping; main clock needs moderate accuracy. |

| Advanced Driver-Assistance Systems (ADAS) | High accuracy crystal, Ultra-stable quartz crystal | Extreme precision is critical for radar, LiDAR, and camera synchronization. Tolerance often below ±10 ppm. |

| Powertrain & ECU | AEC-Q200 compliant automotive crystal, Through-hole or Cylindrical crystal resonator in some legacy designs | Must meet highest reliability standards (AEC-Q200). Resistance to thermal shock and vibration is paramount. |

Step 3: Evaluate Supplier Capabilities & Compliance

Technical specs are only half the story. Your supplier's reliability is the other half. When engaging in crystal resonator sourcing, ask these questions:

- Do they have automotive experience? Look for suppliers whose products are "designed for" automotive use, not just "used in".

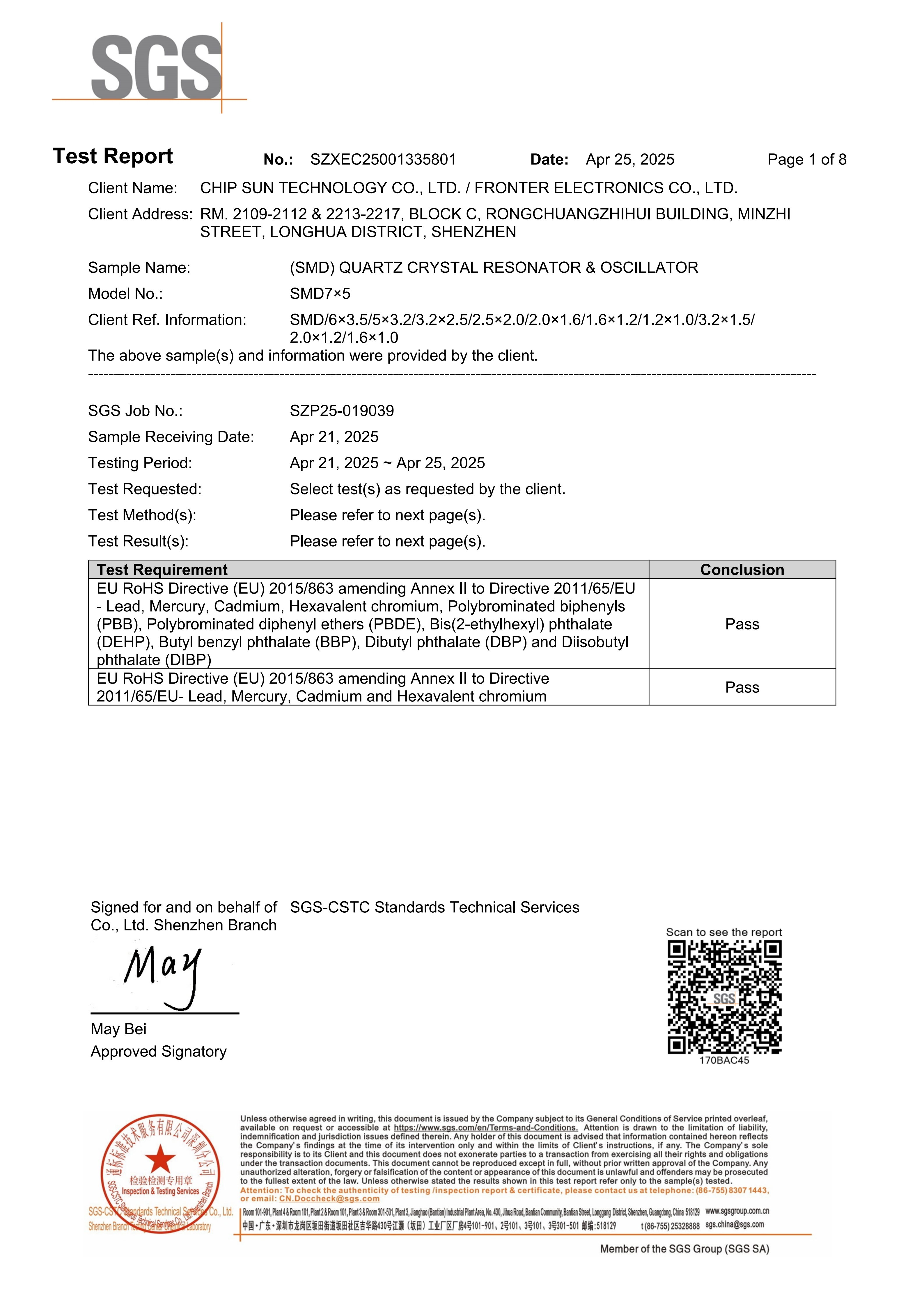

- What certifications do they hold? Compliance with RoHS and REACH is a baseline. For instance, Fronter Electronics provides comprehensive RoHS test reports for its entire range, including SMD quartz crystal resonators and HC-49 series parts, ensuring environmental regulation adherence.

- Can they provide consistent quality at scale? Automotive production runs are long and volumes are high. A supplier like Fronter, with its two automated production facilities and advanced testing machines, is built for this demand.

- Do they offer engineering support? Can they help with quartz crystal model selection or custom frequency control devices?

Spotlight: Fronter's FT Brand in Automotive Electronics

Since its founding in 1991, Fronter Electronics Co., Ltd. has evolved into a National High-Tech Enterprise, with its FT brand becoming synonymous with reliability in frequency components. For automotive clients, Fronter offers a critical advantage: a full portfolio of AEC-Q200 compliant (or equivalent reliability-tested) crystal resonators.

Their product line is vast, covering everything from the tiny SMD2012 and SMD3215 resonators for space-constrained telematics units to robust HC-49SMD and cylindrical crystal resonator options for under-the-hood applications. Their 32.768 kHz crystal resonator series offers excellent long-term stability for vehicle event data recorders and dashboard clocks.

More than just a manufacturer, Fronter provides R&D solutions and turnkey services, working closely with OEMs, ODMs, and EMS providers to integrate the perfect quartz resonator into complex systems. You can reach their technical sales team at sales@chinafronter.com or via WhatsApp: +86 18903022818.

Step 4: Prototype, Test, and Validate

Never skip this phase. Once you have a shortlist of components (e.g., a specific HC49 SMD Crystal or a tuning fork crystal resonator):

- Build Prototypes: Place the surface mount crystal resonator on your board and test under normal conditions.

- Conduct Environmental Stress Testing: Subject the board to temperature cycling, vibration, and humidity per automotive standards. Monitor the crystal 32.768K output or the MHz crystal resonator stability.

- Long-Term Reliability Test: Especially for safety-critical systems, extended life testing is crucial to catch any potential drift in your high accuracy crystal.

This process helps avoid costly recalls or field failures down the line.

Figure 2: Example of Fronter's RoHS compliance documentation for their SMD quartz crystal resonator products, a mandatory requirement for global automotive supply chains.

Conclusion: Precision Drives Performance

Selecting the right crystal resonator is a foundational decision in automotive electronics design. By systematically defining needs, matching components to applications, vetting suppliers like Fronter for quality and compliance, and rigorously testing, engineers can ensure their systems have the reliable heartbeat they need to succeed.

In an era where a car is essentially a network of computers on wheels, the humble quartz crystal remains an indispensable piece of the puzzle. Making a smart choice in frequency control devices today paves the way for innovative and reliable vehicles tomorrow.

Ready to Source High-Reliability Automotive Crystals?

Contact Fronter Electronics today to discuss your project requirements. With decades of expertise in quartz crystal resonators, ceramic resonators, and SAW devices, they are a trusted partner for the automotive industry worldwide.

📞 Tel: +86-755 8345 8798 | 🌐 Website: www.chinafronter.com | 📧 Email: sales@chinafronter.com

Address: Rm. 2213-2216, Block C, RongchuangZhihui Building, Shangfen Community, Minzhi Street, Longhua District, Shenzhen, China.