How to Select the Right Crystal Resonator for Your Automotive Electronics Project: A Comprehensive Guide

The automotive electronics landscape is shifting gears at an unprecedented pace. With the rise of electric vehicles (EVs), advanced driver-assistance systems (ADAS), and in-vehicle infotainment (IVI), the demand for ultra-reliable, high-precision timing components has never been greater. At the heart of these systems lies a critical component: the crystal resonator. Choosing the wrong one can lead to system failures, communication dropouts, or safety risks. This guide will walk you through the essential steps and considerations for selecting the perfect quartz crystal resonator for your next automotive project.

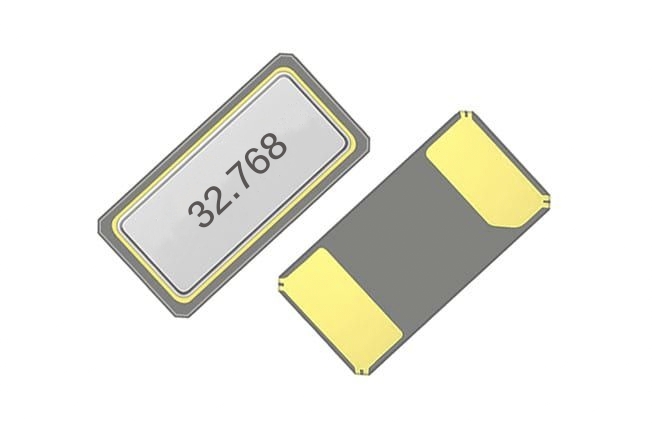

Precision SMD crystal resonators like the FM206A series are engineered for stability in demanding applications.

Step 1: Define Your Core Frequency and Stability Requirements

Your journey begins with the fundamental specification: frequency. Automotive applications use a wide range.

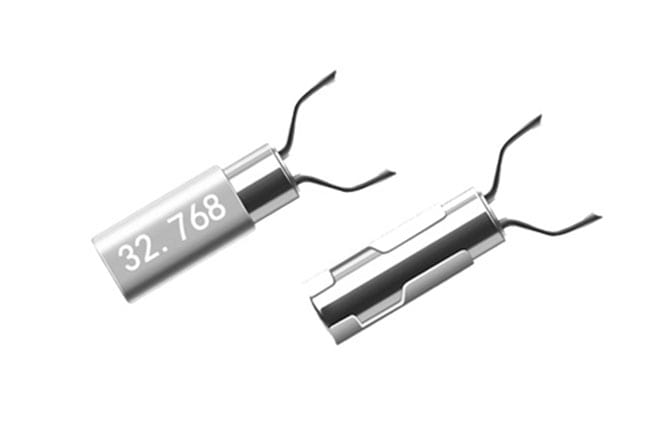

- 32.768 kHz crystal resonator: The workhorse for Real-Time Clocks (RTCs) in dashboards, event loggers, and low-power modules. Its low frequency is ideal for timekeeping with minimal power draw.

- MHz crystal resonator: Ranging from 4 MHz to 50 MHz and beyond, these are the standard for microcontrollers (MCUs), CAN bus controllers, and sensor interfaces. You must match the exact quartz crystal model number required by your MCU datasheet.

- For high-speed communication modules (GPS, V2X), you might need a high accuracy crystal with stability in the ±10 ppm range or better.

Stability over temperature is non-negotiable in automotive crystal applications. A standard resonator might be ±30ppm, but for engine control units (ECUs) or radar, you may need an automotive crystal graded for the AEC-Q200 standard, offering stability as tight as ±10ppm across -40°C to +125°C.

Step 2: Choose the Right Package and Mounting Type

Space, assembly process, and reliability dictate this choice.

- SMD crystal resonator / Surface mount crystal resonator: The dominant choice for modern automotive PCBAs. They save space and are suited for high-speed automated assembly. Common sizes include SMD3215, SMD5032, and HC49 SMD Crystal.

- Through-hole crystal resonator: Such as the classic HC-49U or Cylindrical crystal resonator (DT38/DT26). These offer robust mechanical bonds and are sometimes preferred in prototypes or applications with high vibration, though they are being phased out in favor of SMDs.

- Always consult your PCB designer on footprint compatibility. Fronter Electronics provides detailed datasheets and CAD models for all their SMD crystal packages to streamline this process.

Miniaturized SMD crystal resonators like the SMD3215 enable dense PCB designs in modern telematics units.

Step 3: Evaluate Environmental and Quality Certifications

This is where reputable suppliers separate themselves. For automotive crystal sourcing, you cannot overlook certifications.

- AEC-Q200: The de facto quality standard for passive components in automotive applications. It mandates rigorous stress tests for temperature cycling, humidity, bias, and mechanical shock.

- RoHS & REACH Compliance: Ensures the component is free of hazardous substances. For instance, Fronter Electronics holds multiple RoHS Test Reports (e.g., SZXEC25001335801 for SMD types) for its full range, proving environmental compliance.

- Supplier Audit: Does the manufacturer, like Fronter, have IATF 16949 certified production facilities? Their two automated plants in Shenzhen are equipped to deliver the consistency required for automotive-grade Frequency Control Devices.

Step 4: Consider Application-Specific Nuances

Different automotive subsystems have unique needs.

ADAS & Radar: Requires high accuracy crystal with exceptional phase noise performance and low jitter to ensure precise object detection and distance measurement.

Infotainment & Telematics: Often uses a MHz crystal resonator for the main processor and a separate 32.768 kHz crystal for the RTC. Vibration resistance is key.

Body Control Modules (BCMs): Reliability over a wide temperature range is critical. A robust Quartz crystal resonator or a cost-effective Ceramic resonator might be evaluated based on precision needs.

EV Battery Management Systems (BMS): Needs components with high reliability and longevity. The tuning fork crystal resonator structure used in watch crystal 32.768K devices is often chosen for its proven stability in low-power timing circuits.

Step 5: Partner with a Capable Supplier for Sourcing and Support

Your crystal resonator sourcing strategy is as important as the technical selection. Here’s where a partner like Fronter Electronics Co., Ltd. adds immense value.

Founded in 1991 and recognized as a National High-Tech Enterprise, Fronter (brand FT) specializes in the R&D and production of a full spectrum of Frequency Control Devices. For your automotive crystal project, they offer:

- Comprehensive Product Range: From 32.768 kHz crystal resonator to MHz crystal resonator, in both SMD and through-hole packages (HC-49S, DT38, SMD5032, etc.).

- Custom R&D: They can develop or tailor quartz crystal solutions according to your specific frequency, stability, and size requirements.

- Proven Quality: All products comply with RoHS and REACH, with documented test reports available. Their automated production ensures consistency.

- Direct Support: Their technical team can provide guidance on quartz crystal model number selection, circuit layout for optimal SMD crystal frequency stability, and troubleshooting.

For a consultation or to request samples for your automotive project, contact Fronter directly:

Fronter Electronics Co., Ltd.

Tel: 86-755 8345 8798

E-mail: sales@chinafronter.com

WhatsApp: +86 18903022818

Website: www.chinafronter.com

Address: Rm. 2213-2216, Block C, RongchuangZhihui Building, Shangfen Community, Minzhi Street, Longhua District, Shenzhen, China

Conclusion: Precision Timing Drives Automotive Innovation

Selecting the right crystal resonator is a detailed but crucial process that balances frequency, package, environmental robustness, and application demands. By following these steps and partnering with an experienced, certified manufacturer like Fronter, you can secure a reliable timing heartbeat for your automotive electronics, ensuring performance, safety, and longevity on the road ahead. Don't treat crystal resonator sourcing as an afterthought—it's a strategic decision that can define your product's success.