How to Select the Right Crystal Oscillator for Your Automotive Electronics Project: A Practical Guide

The rapid evolution of automotive electronics—from advanced driver-assistance systems (ADAS) to in-vehicle infotainment and vehicle-to-everything (V2X) communication—places unprecedented demands on timing components. Selecting the correct crystal oscillator is no longer a minor detail; it's a critical decision impacting system reliability, performance, and compliance. This guide walks you through the key considerations, helping you navigate the specs to find the perfect timing solution for your next automotive project.

1. Understand the Core Requirements of Your Application

Start by defining the operational environment and performance needs. An infotainment system's clock oscillator has different priorities than one for an engine control unit (ECU) or a tire pressure monitoring sensor.

- Temperature Range: Automotive-grade components must typically operate from -40°C to +125°C, sometimes higher. A standard quartz crystal oscillator might drift, making a TCXO (Temperature Compensated Crystal Oscillator) or even an OCXO (Oven Controlled Crystal Oscillator) necessary for critical timing paths.

- Stability & Phase Noise: Radar and communication modules require high stability oscillators with low phase noise. For GPS modules and cellular V2X, a TCXO oscillator with stability in the ±0.5 ppm to ±2.5 ppm range is common.

- Power Consumption: For always-on or battery-backed modules (e.g., telematics), a low power consumption oscillator is vital to extend battery life.

- Physical Size & Mounting: Space is always at a premium. SMD oscillator packages, such as the popular 4-pin SMD oscillator, are the norm. Ensure the footprint matches your PCB design.

A selection of precision oscillators, including SMD types, critical for modern automotive designs.

2. Decoding Oscillator Types: Which One is for You?

Here’s a quick comparison of common quartz oscillator types used in automotive electronics:

| Type | Key Feature | Typical Stability | Best For |

|---|---|---|---|

| Clock Oscillator (XO) | Basic, cost-effective | ±10 to ±100 ppm | Non-critical timing, displays |

| TCXO Oscillator | Internal temperature compensation | ±0.5 to ±2.5 ppm | GPS, V2X, infotainment |

| OCXO Oscillator | Oven-controlled, highest stability | ±0.001 to ±0.1 ppm | Base stations, radar, high-end test equipment |

| VCXO / VCTCXO | Voltage-controlled frequency adjustment | Varies (e.g., ±10 to ±50 ppm pullability) | Clock recovery, synchronization loops |

| Differential Oscillator | Differential output (LVDS, HCSL) | As per base type (XO, TCXO) | High-speed SerDes, FPGAs, reducing EMI |

For applications requiring frequency agility, a programmable oscillator offers flexibility by allowing frequency setting via software or pins, reducing inventory complexity.

3. The Critical Role of Quality and Certification

In automotive, failure is not an option. Beyond specifications, supplier reliability is paramount. Partner with manufacturers who adhere to stringent quality standards.

- AEC-Q200 Compliance: This is the baseline qualification for passive components in automotive applications. It ensures reliability under stress tests like temperature cycling, humidity, and mechanical shock.

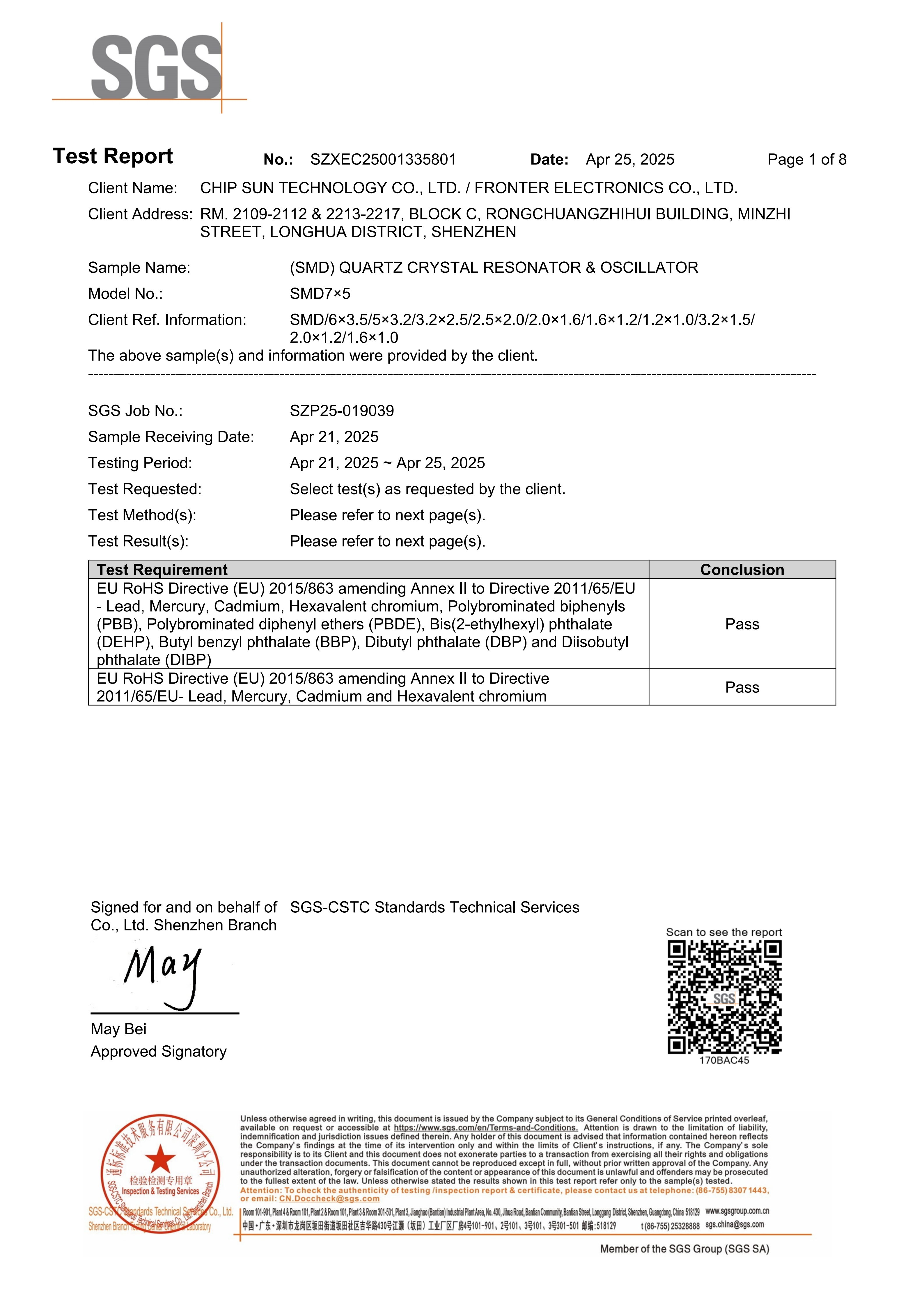

- Environmental Regulations: Ensure all components, including your active crystal oscillator, comply with RoHS and REACH directives. Reputable suppliers like Fronter Electronics provide comprehensive test reports for their products.

Example of a RoHS test report for SMD quartz crystal resonators and oscillators, a standard commitment from quality-focused manufacturers.

Companies like Fronter Electronics Co., Ltd., founded in 1991 and recognized as a National High-Tech Enterprise, invest heavily in quality infrastructure. With two automated production facilities equipped with advanced manufacturing and testing machines, they ensure every precision oscillator meets spec. Their FT brand products are widely used in automotive electronics, among other fields.

State-of-the-art automated production line at Fronter Electronics ensuring consistent quality for SMD oscillators and other components.

4. Partnering with the Right Supplier: Beyond the Part Number

The best crystal oscillator supplier offers more than just components. Look for these value-added services:

- Technical Support & R&D Collaboration: Can they develop custom solutions, like a specific VCTCXO or a differential output oscillator tailored to your board's EMI needs?

- Supply Chain Stability: Do they have control over their manufacturing, like Fronter does with its own factories, to guarantee supply?

- Global Support: For international projects, suppliers with responsive global communication channels (email, WhatsApp) are essential.

For instance, Fronter Electronics provides full R&D solutions and turnkey services, supporting OEMs, ODMs, and EMS providers from concept to mass production. You can reach their team at sales@chinafronter.com or via WhatsApp at +86 18903022818 to discuss your automotive crystal oscillator requirements.

Final Checklist Before You Order

- ✅ Defined operating temperature range and required frequency stability.

- ✅ Chosen between XO, TCXO, OCXO, or VCXO based on application needs.

- ✅ Selected package type (SMD oscillator, 4-pin, etc.) and output type (CMOS, LVDS, etc.).

- ✅ Verified supplier qualifications (AEC-Q200, IATF 16949, RoHS/REACH certificates).

- ✅ Confirmed availability of technical support and design-in assistance.

By following this structured approach, you can confidently select a high stability, reliable quartz crystal oscillator that will keep your automotive electronic systems running flawlessly for years to come.

Explore the full range of timing solutions from a trusted partner like Fronter at their official website: www.chinafronter.com.